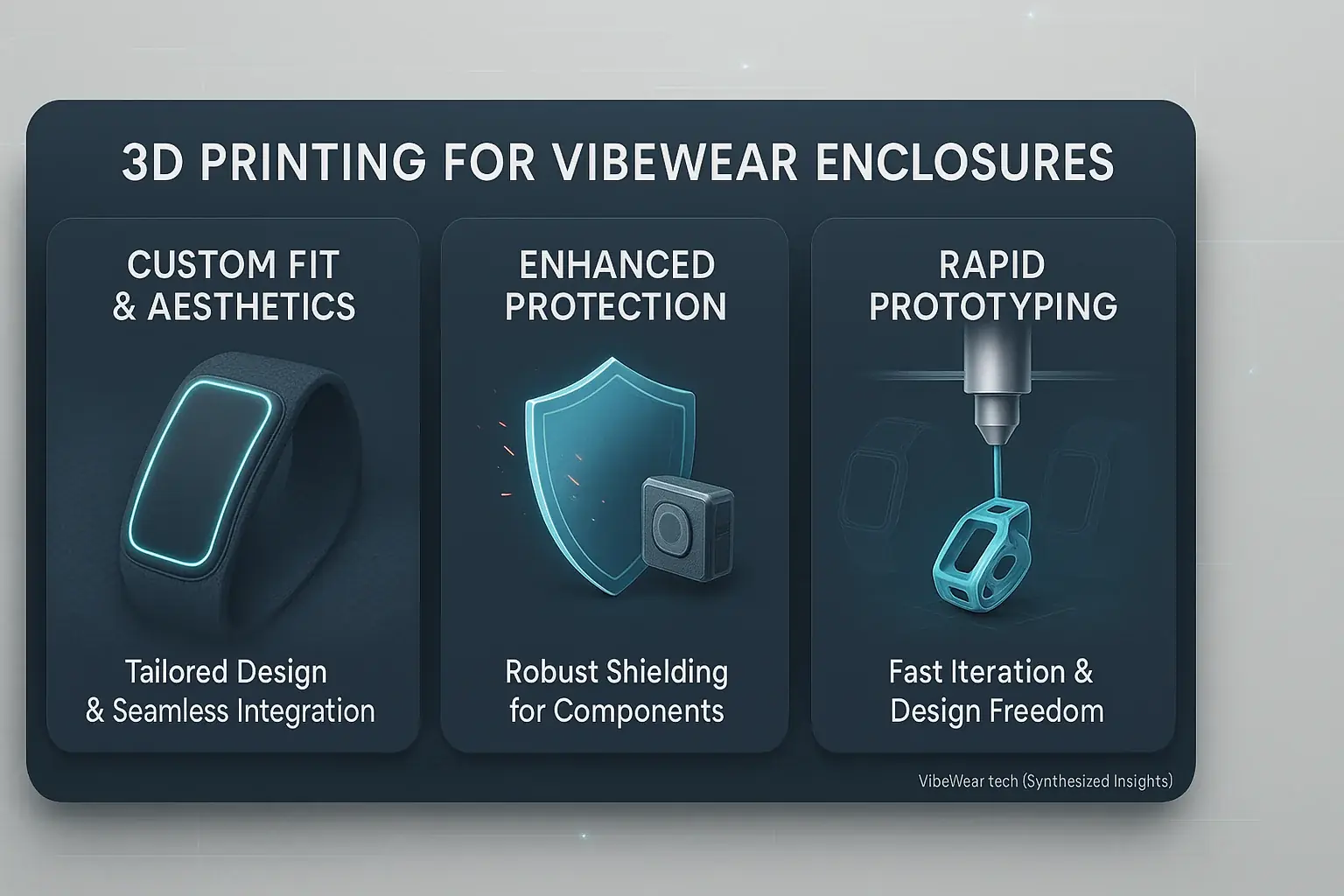

Why 3D Print Your VibeWear Enclosures? Beyond Off-the-Shelf Protection

Struggling to fit standard cases around your VibeWear components? Generic enclosures often create more problems than they solve. 3D printing offers a radical solution for your mood-adaptive streetwear. This technology empowers you to craft perfectly tailored housings for E-Ink displays, microcontrollers, and sensors. Your custom enclosure transforms a loose electronic part into a truly integrated, protected element of the garment.

This precise customization delivers immediate practical benefits. 3D printed cases conform flawlessly to even uniquely shaped VibeWear electronics. No more awkward bulges. Many creators find standard boxes make wearables uncomfortable or restrict movement. A specifically designed enclosure, however, shields delicate sensors and boards from daily wear, accidental bumps, and even moisture. Your vital tech gains robust protection.

Beyond simple safeguarding, 3D printing unlocks immense aesthetic flexibility for VibeWear. You can design enclosures that disappear into the fabric. Match the garment's exact color and texture. Alternatively, make the 3D printed housing a deliberate, visible design feature, enhancing your VibeWear's unique style. This isn't just about protecting electronics; it's about elevating the entire wearable experience to be truly seamless and expressive.

Designing Your 'Second Skin': 3D Modeling Basics for Wearable Tech

Consider your wearable's electronics housing. It is a true second skin. Thoughtful 3D modeling for wearables means more than just fitting components. User comfort is paramount. Seamless interaction with body and fabric defines success. We've learned accessible software empowers creators. Tinkercad helps beginners start. Fusion 360 provides advanced tools for intricate designs.

Functional design requires careful planning. How do you achieve precise component fit? E-Ink boards need dedicated space. Batteries and sensors also demand secure placement. Internal supports prevent unwanted movement. Smart cable routing avoids troublesome snags. Proper ventilation manages heat. This prevents electronics from overheating. Imagine a maker's early design. It lacked airflow. The E-Ink board overheated. Its display became erratic. Loose components also rattled. Careful planning avoids these issues.

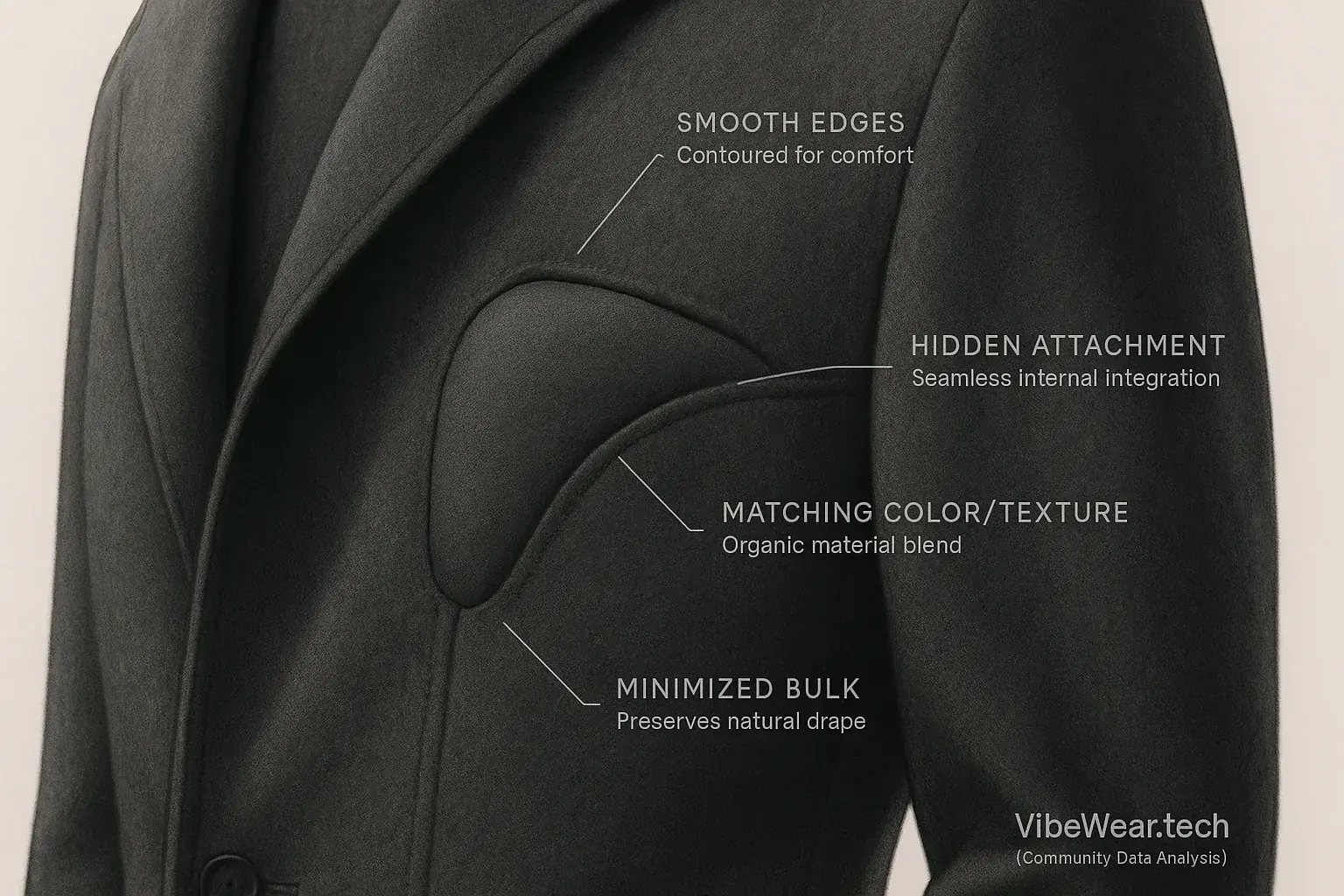

Ergonomics ensure lasting wearer comfort. Smooth, rounded edges prevent skin chafing. Consider natural body contours in your design. Attachment points must integrate seamlessly with fabric. Loops for sewing offer flexibility. Flat surfaces work well for adhesives. These methods should not compromise the garment's intended drape. Aesthetics also guide your design choices. Will the enclosure be subtle? Or will it become a bold statement piece?

Iteration perfects your enclosure design. 3D printing allows rapid prototyping. You can print new versions quickly. Test the fit. Evaluate function. Redesign with ease. Many successful makers embrace this cycle. This path leads to the ideal enclosure for your VibeWear project.

Choosing Your Material: Filaments for Flexible & Durable VibeWear

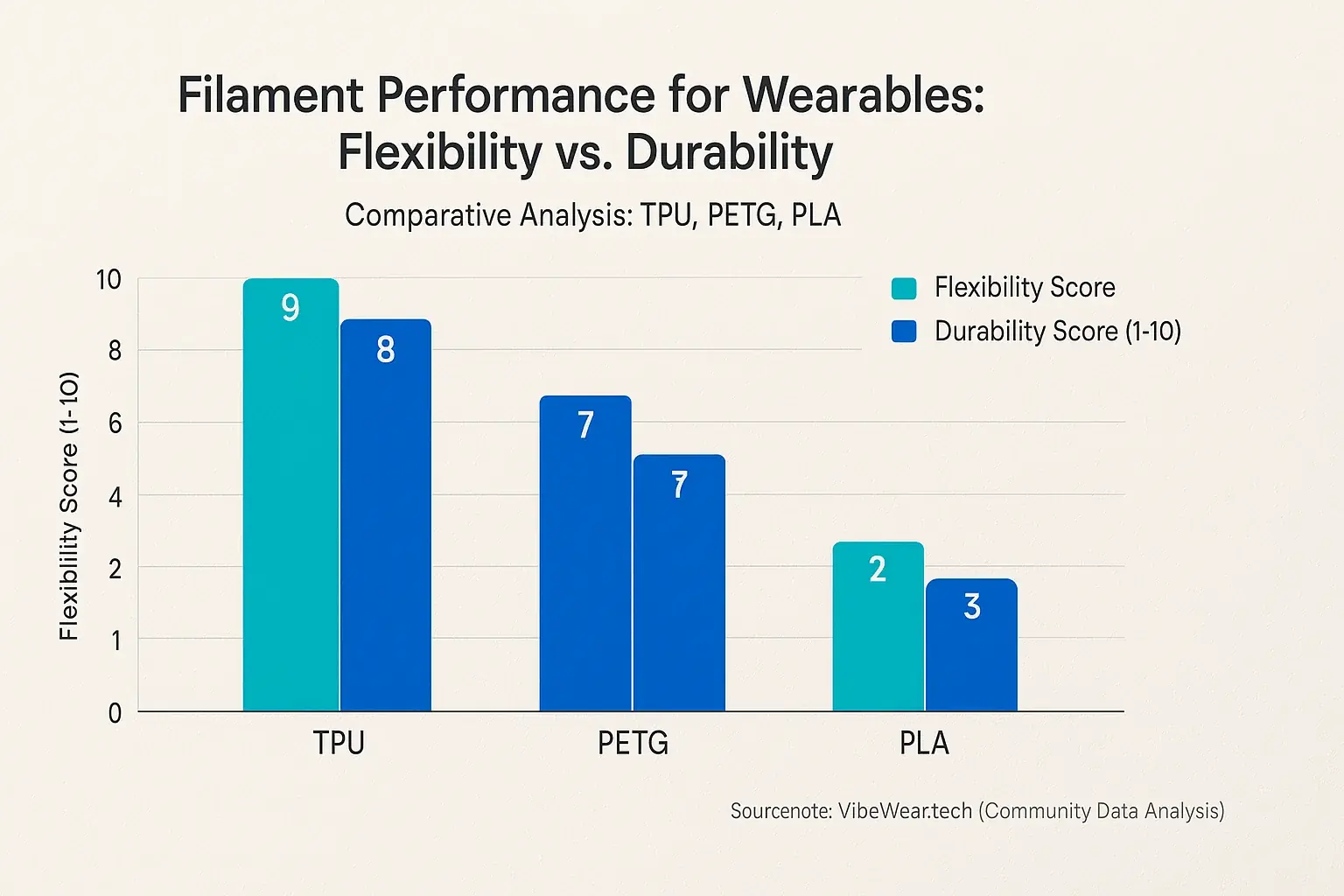

Filament choice is critical for VibeWear. Your material selection directly impacts enclosure functionality. It also affects comfort and longevity. VibeWear enclosures must endure daily life. Movement, sweat, constant bending define their use. This differs from static prints. The main contenders? TPU, PETG, and PLA each offer distinct properties for wearable tech.

TPU shines for flexibility. This material excels where components must bend with body movements. It also provides excellent impact resistance. Makers often choose TPU for wristbands or flexible panels. They report it moves comfortably without cracking, even after months of active wear. Printing TPU can be challenging. Its flexibility demands careful retraction settings. Stringy first prints? Do not despair.

PETG presents a compelling middle ground. It balances strength with good durability. PETG also resists moisture well. These traits make it ideal for more rigid, protective VibeWear components. PLA, while easy for beginners to print, has drawbacks. Its brittleness and low heat resistance make PLA less suitable for items worn directly against the body.

VibeWear's research into emerging materials indicates new possibilities. Bio-based flexible filaments are gaining traction. They offer performance similar to TPU. Their footprint is eco-friendlier. These advanced materials promise enhanced comfort. They also reduce environmental impact. This is a win-win for conscious VibeWear creators.

Printing Perfection: Tips for Successful Wearable Enclosures

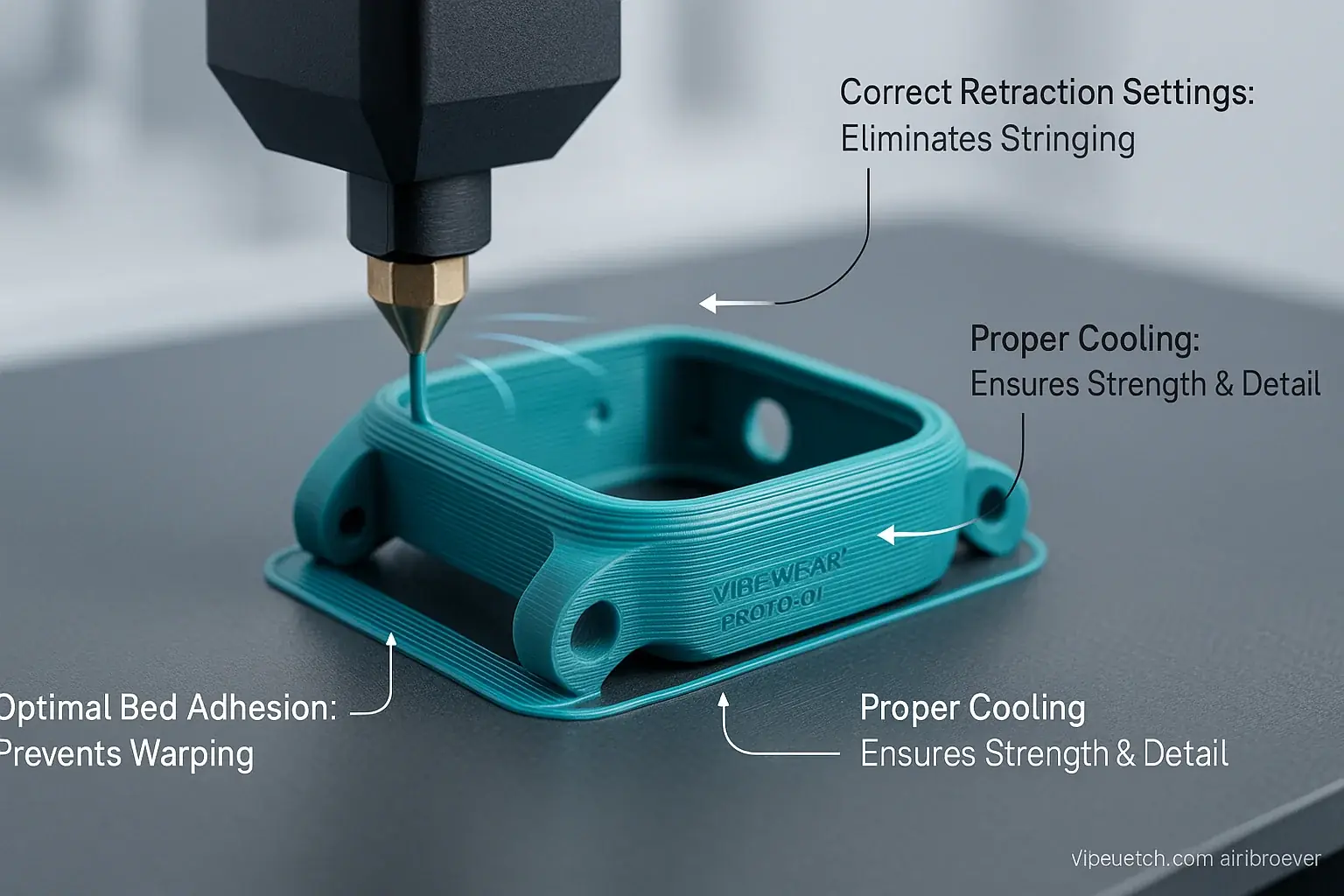

Your brilliant wearable design demands flawless execution. Even the most innovative 3D model can yield disappointing results without sharp printing techniques. Wearable enclosures, especially, require precision. They need to fit comfortably and protect sensitive electronics. Let's explore some practical steps for 3D printing success.

Optimal printer settings are absolutely fundamental for your enclosure's durability. Ever had a print detach from the bed halfway through? You get a plastic spaghetti mess instead of your carefully designed part. That is often a bed adhesion problem. Ensuring your filament adheres properly prevents warping. Correct nozzle and bed temperatures, alongside managed print speed and cooling, create strong, smooth prints. This becomes even more vital when working with flexible filaments for wearable comfort.

Complex wearable shapes often necessitate support structures. Strategic placement allows intricate designs. Removing supports cleanly, however, is key to a professional finish. Damaged surfaces compromise aesthetics and comfort. Post-processing techniques like light sanding or vapor smoothing can elevate your print's tactile quality. One crucial piece of advice: always test fit your enclosure with the actual electronics before any final finishing. A tiny dimensional error can mean a frustrating reprint. Check twice, print once for critical components.

You might encounter issues like stringing or slight layer shifts. View these as learning opportunities. Every maker faces them. Troubleshooting these common 3D printing challenges sharpens your skills. This refinement process makes your next VibeWear project even better. Patience pays.

Seamless Integration: Designing for Comfort & Aesthetics in VibeWear

VibeWear elevates fashion. It's an experience. Tech is just the tool. A great enclosure feels organic. It merges with the garment. This demands thoughtful design. Comfort. Aesthetics. These are paramount.

User comfort truly shapes the VibeWear experience. Rounded enclosure edges prevent skin irritation. Smooth surfaces are essential. This is especially true for components worn directly against the body. Imagine a rigid, bulky tech piece. It digs. It chafes. Users complain. Minimizing bulk ensures natural garment drape. Lightweight design allows free movement. The garment should flow, not fight the body.

Aesthetic integration is an art. How does an enclosure become part of the vision? It can blend seamlessly. Or, it can stand out. Deliberately. Color-matching filament to fabric creates subtlety. Textured filaments can complement textile weaves. Enclosures might mimic a jacket's seam lines. Or a pocket's curve. Attachment methods also influence style. Internal pockets hide the tech. Fabric loops offer discreet connection points. Conversely, visible attachments can become bold, decorative features. Think custom clasps. Or articulated segments.

This thoughtful integration transforms VibeWear. It moves beyond a mere gadget. It becomes a cohesive fashion statement. The technology enhances the wearer. It doesn't encumber them. This is where design and engineering meet. Beautifully.

Inspiring Builds: Showcase of Creative 3D-Printed VibeWear Enclosures

VibeWear's exploration into the maker sphere uncovers stunning enclosure concepts. These visions spark real innovation. Diverse 3D-printed forms can truly ignite your VibeWear project creativity. 3D printing offers total freedom. It unlocks boundless personal expression for your mood-adaptive streetwear.

Picture a sleek, minimalist shell. It almost vanishes into a jacket's seam. The E-Ink display? Revealed only by mood. Or envision a daring, angular structure. This becomes a hoodie’s undeniable focal point. Its lines channel futuristic urban design. These conceptual discoveries showcase incredible range: subtle integration, overt artistry, even organic forms that flow like textiles.

Your brilliant designs? Share them. VibeWear sees the community as a hotbed of shared creativity. Fuel the movement. Inspire everyone.