Embarking on Your VibeWear Build: Why Components Matter

Ever felt that surge of excitement imagining your own mood-adaptive hoodie? Then you stared at a blank screen, wondering where to even begin. You are not alone. The journey from concept to glowing reality starts, quite literally, with the right parts. Adaptive fashion's magic truly begins here: understanding its building blocks.

Choosing the right components is not just about functionality. It defines your project's success. It ensures durability. It even impacts comfort. Many aspiring creators learn this hard way. A flimsy connection or an underpowered microcontroller can quickly turn a dream project into a frustrating tangle. We've seen countless community discussions about projects that never quite 'vibed' because core parts, like the E-Ink display or sensors, were not suited for wearable tech.

So, what now? This guide offers a practical, curated walkthrough. We explore key VibeWear DIY components. You learn how to pick them effectively. This saves makers precious time. And many potential headaches. Get ready to build.

E-Ink Panels: Your Wearable Canvas

E-Ink forms your VibeWear canvas. Its unique properties truly shine. Low power consumption is paramount. Sunlight readability excels. These traits make E-Ink ideal for dynamic clothing. Other displays cannot match this performance. Imagine your shirt. Its design changes instantly. The battery endures for days. This is E-Ink's core magic. It sits at the heart of VibeWear. Makers frequently select it. E-Ink looks fantastic under bright sunlight. A phone screen simply washes out.

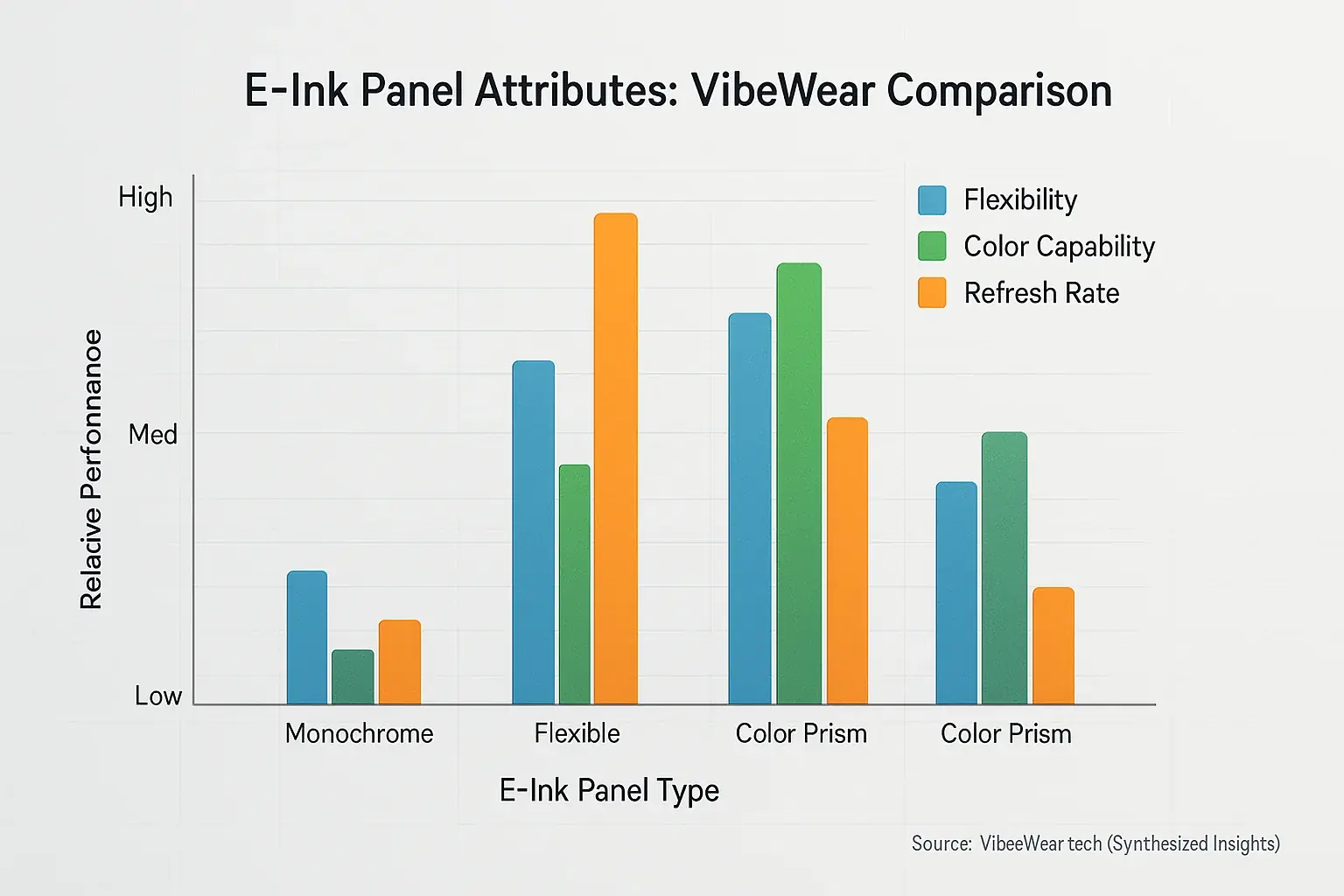

Makers explore diverse E-Ink panels for projects. Monochrome E-Ink offers robust simplicity. Color E-Ink, like E-Ink Prism, adds vibrant visual expression. Flexible E-Ink enables innovative garment shapes. Monochrome panels are generally cost-effective. They are also quite durable. This makes them excellent for initial VibeWear experiments. Color displays create stunning, dynamic aesthetics. They typically cost more. They can also be more delicate. Flexible E-Ink conforms to fabric contours seamlessly. Its integration often demands greater skill. An important point. Many beginners gravitate towards color E-Ink first. The higher cost can quickly stall a project. Fragility also presents a common, frustrating hurdle. These factors frequently derail ambitious first builds. A simple monochrome panel often delivers sufficient impact. It proves far more forgiving for your initial VibeWear creation.

You can source E-Ink panels from several established suppliers. Adafruit stocks many developer-friendly options. Waveshare provides diverse E-Ink modules and kits. SparkFun also carries useful displays for makers. When purchasing, consider key specifications carefully. Panel size dictates your design's active visual area. Resolution, often in Dots Per Inch (DPI), affects image clarity and detail. The communication interface, like SPI or I2C, determines microcontroller compatibility. Do you need high detail or a large area? Plan ahead.

Choosing an E-Ink panel involves balancing critical attributes. Flexibility varies significantly. Rigid panels are easiest to mount securely. Semi-flexible panels can conform to gentle curves on clothing. Fully flexible, foldable E-Ink is less common and more challenging for DIY projects currently. Color capability ranges from basic to rich. Monochrome offers excellent contrast and fast updates. Limited color panels (e.g., black, white, and one accent like red or yellow) provide a middle ground. Full color E-Ink Prism technology creates vibrant, multi-hued designs but often has slower refresh rates and higher power use during changes. Refresh rate itself is a key consideration. E-Ink updates are inherently slower than LCDs; full-screen changes can take seconds, while partial updates are quicker. Power consumption remains E-Ink's champion feature, using energy almost exclusively during display changes.

Sensors: Giving Your Clothes a 'Sixth Sense'

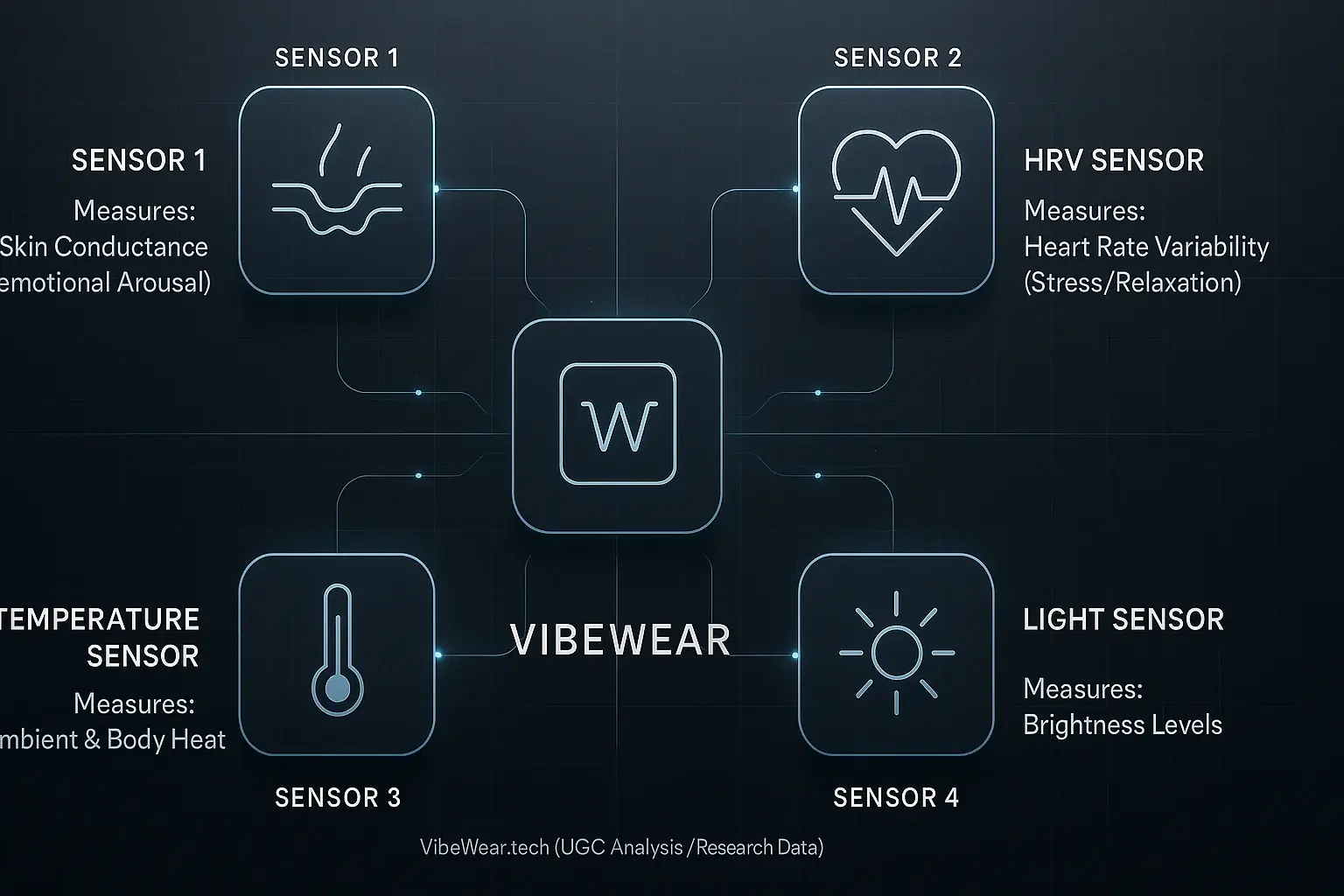

Sensors are VibeWear's vital senses. They gather crucial data. Ever wished your jacket could subtly tell you if the room's vibe was off? Or if you were getting stressed? That's where sensors come in. These components are the unsung heroes. They silently gather information. This information makes your VibeWear truly adaptive.

Biometric sensors track your body's subtle signals. Environmental sensors monitor your immediate surroundings. Consider Electrodermal Activity (EDA) sensors. They measure minute skin conductance changes. These changes often link to emotional arousal. Makers use EDA for direct mood input into designs. Heart Rate Variability (HRV) sensors are also key. They track tiny variations in time between heartbeats. HRV offers powerful insights into your stress or relaxation levels. Why these for makers? They provide deeply personal context for adaptation. Temperature sensors detect ambient heat or your body's warmth. Your VibeWear could then adapt to a chilly office. Light sensors gauge brightness. Garments might shift patterns from bright daylight to dim interiors. Sound sensors perceive noise. Your clothing could even react to a sudden hush or a loud concert.

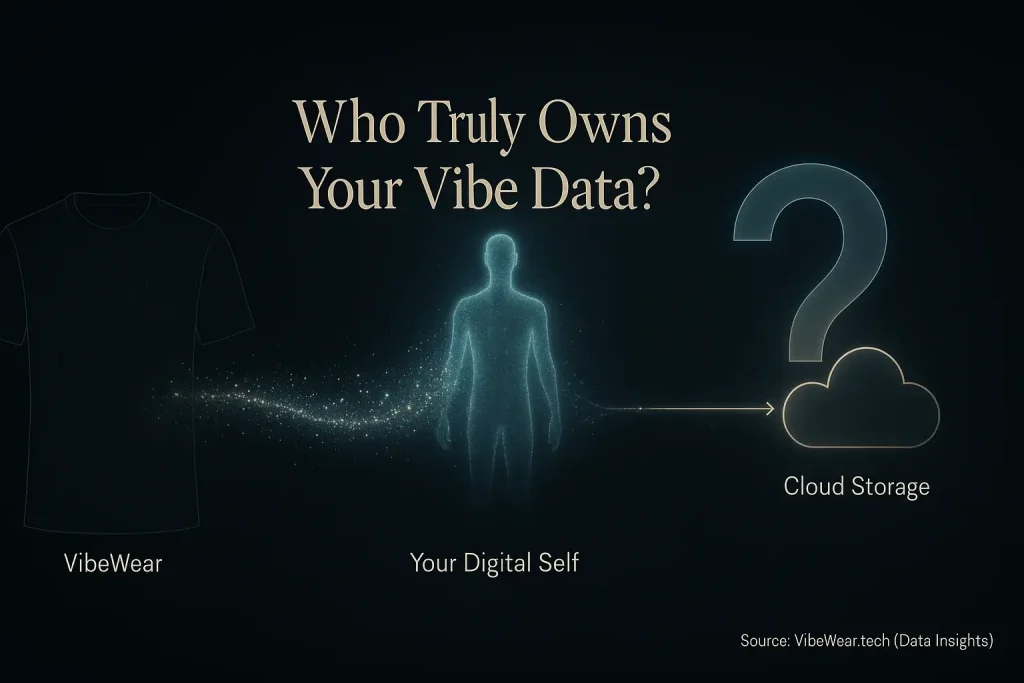

Sensor selection involves practical tradeoffs. Size matters for seamless garment integration. Power efficiency extends wearable battery life. Accuracy directly impacts VibeWear's responsiveness. Ease of connection to microcontrollers speeds up development. VibeWear's proprietary analysis highlights a common pitfall. Many makers overlook sensor data 'noise'. A cheap sensor might give you readings. But what if movement or static creates interference? Your 'mood-adaptive' shirt could display random, meaningless patterns. This is a crucial point. Investing in quality sensors is vital. Understanding data filtering techniques is equally important. It's about balancing ambitious designs with reliable performance.

So, diverse sensors feed VibeWear different data streams. Biometric sensors, like EDA sensors, track internal states. EDA specifically measures skin conductance changes, reflecting emotional arousal. HRV sensors detect subtle heart rate pattern shifts, indicating stress or calm. Environmental sensors capture external conditions. Temperature sensors measure heat. Light sensors gauge brightness levels. Sound sensors register ambient noise. Each sensor type provides a unique input. Together, they paint a richer picture for adaptive responses.

The Brains of Your Outfit: Choosing the Right Microcontroller

Microcontrollers (MCUs) are central. They act as the brain. Think of your VibeWear as a smart organism. The E-Ink is its skin. Sensors are its senses. And the microcontroller? That's the brain, making all the decisions. Picking the right one is like choosing the right personality for your project.

Comparing MCUs for wearables reveals key differences. The Arduino family offers simplicity. Arduino Nano or LilyPad suit small designs perfectly. They work well for straightforward VibeWear. ESP32 boards bring powerful Wi-Fi and Bluetooth. This connectivity expands project possibilities immensely. ESP32s can demand more power. Their programming can challenge newcomers.

Sourcing MCUs needs practical thought. Look for development boards. Integrated USB simplifies programming. It really does. Consider your learning curve too. Many beginners get overwhelmed by MCU options. The 'best' one isn't always the most powerful. It's the one fitting your project's needs. And your current skill level. Without causing a meltdown. Starting simple often leads to more success. Plain truth.

The trade-offs become clear. Size matters. Arduino Nanos are tiny. ESP32 modules can be larger but pack features. Connectivity varies greatly. Arduinos often need extra shields for wireless. ESP32s have Wi-Fi and Bluetooth built-in. Power consumption also differs. Simpler Arduinos sip power. ESP32s can be thirstier, especially with radios active. Ease of use? Arduinos are beginner-friendly. ESP32s offer more but require more learning.

Keeping the Vibe Alive: Powering Your Wearable Tech

You've got the E-Ink glowing. Sensors are sensing. The microcontroller is humming. But then, poof! Your VibeWear dies after an hour. Power is the unsung hero. It's often the biggest headache if not planned right. Careful planning is vital.

Wearables demand specific batteries. LiPo batteries offer good energy density. Handle them very carefully. Flexible batteries can conform to your VibeWear designs. Their capacity, measured in mAh, is a key factor. Many beginners underestimate how quickly small batteries drain with active sensors or frequent E-Ink updates. The real secret to a long-lasting VibeWear piece often lies in smart power management. Think efficiency. Not just capacity. Microcontroller sleep modes, for instance, dramatically extend operational time.

Sourcing suitable batteries requires diligence. Choose reliable suppliers. Always. Match battery voltage to your VibeWear components precisely. Mismatches can cause serious damage. Use proper charging circuits, especially for LiPo batteries. This protects your battery. It ensures longevity. What about those charge cycles? They directly impact your wearable's usable lifespan.

Weaving the Circuits: Conductive Threads & Smart Fabrics

Wires are stiff, right? Not exactly fashion-friendly. Imagine sewing your circuits directly into fabric! Conductive threads and fabrics make this possible, transforming your garment into a soft, flexible circuit board. These materials are key to truly wearable electronics. They allow circuits to bend, stretch, and move naturally with the body.

Conductive threads offer several options for your projects. Silver-plated threads conduct electricity exceptionally well, ideal for delicate signals. Stainless steel threads boast superior strength and better washability. Conductive fabrics can create larger integrated sensor areas or even flexible heater elements. These innovative materials replace traditional, rigid wires in VibeWear creations. Which type best suits your specific design needs?

Working with these threads demands care. Avoid shorts by keeping paths separate. Connections must be robust. Many beginners stitch conductive thread like ordinary cotton, a path to frustratingly intermittent circuits. The unspoken truth? Use wide, flat stitches for solid contact and add fabric glue for strain relief; these details ensure reliable VibeWear. Always source materials from specialized electronics or textile suppliers.

Your Component Hunt: Where to Find Quality Parts

Okay, you know what you need for your VibeWear project. Now, where do you actually buy these futuristic bits and pieces? The internet is vast. Finding trustworthy suppliers for E-Ink, tiny sensors, and wearable-friendly microcontrollers can feel like a genuine treasure hunt, demanding patience.

Many makers trust specific online retailers for their VibeWear components. Adafruit supports beginners with kits and strong documentation, while SparkFun boasts a wide selection and detailed guides. Waveshare excels for E-Ink displays. For an industrial-grade range, Digikey and Mouser carry vast electronic component inventories.

Smart sourcing involves a few key steps. Check supplier reviews thoroughly. Compare prices and understand all shipping implications. Crucially, double-check component specifications. The unspoken truth? Investing in quality parts from reputable suppliers avoids huge headaches with faulty items or no documentation, saving you considerable project time and frustration.

Ready to Build: Your VibeWear Journey Awaits

You've now got the inside scoop on VibeWear: E-Ink canvas, tiny brains, interwoven threads. This knowledge is your blueprint. It helps bring dynamic fashion to life. Thoughtful component selection is foundational for any project. Understanding these blocks is your first step to making your adaptive fashion dreams real.

Adaptive fashion awaits your unique touch. Don't be afraid to start small; experiment freely and learn from every connection. Your journey into creating expressive techwear begins now. The VibeWear community actively supports makers like you. So, what will your VibeWear say about you?