Beyond the Hype: The Real Hurdles of E-Ink in Fashion

Imagine your shirt changing patterns with your mood. Sounds incredible. Right? But the journey from concept to closet is riddled with real-world hurdles. E-Ink fashion truly captivates. Yet, many unspoken truths lie beneath the surface of initial excitement. VibeWear has dug deep into what really holds back mass adoption. We are here to pull back the curtain, moving beyond marketing hype.

So, what are these core E-Ink apparel challenges? Think durability. Can e-ink clothing survive daily wear and tear? Then consider washability; a critical, practical concern for any garment. Keeping these smart clothes powered presents another complex puzzle. And of course, the current cost of e-ink components impacts accessibility. These are the practical realities.

VibeWear commits to a transparent examination of these E-Ink fashion hurdles. Our analysis reveals why each challenge matters profoundly for both consumers and creators. We explore the tough questions. We also spotlight emerging solutions and ongoing research. This is a realistic look at the path forward for mood-adaptive e-ink fashion.

The Daily Grind: Making E-Ink Displays Survive Real Life Wear & Tear

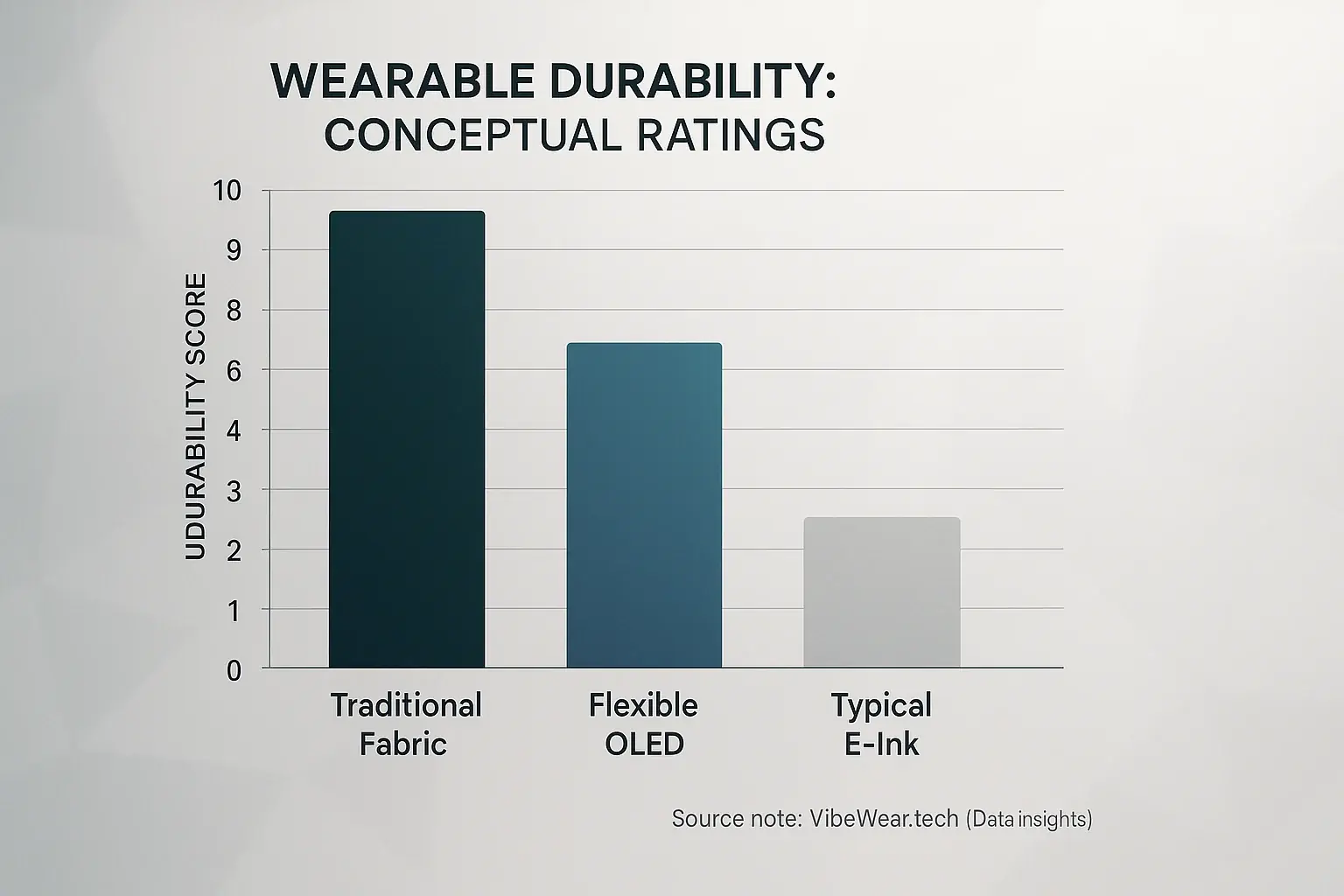

Your hoodie gets tossed, stretched, and shoved into backpacks, scraping rough surfaces. Can E-Ink screens truly handle this daily grind? Wearable displays face constant mechanical stress—bending, impacts, abrasion—unlike their static counterparts. This presents a formidable engineering hurdle for integrated mood-adaptive apparel.

Our deep dive into material science and early adopter feedback reveals an unspoken truth. Early E-Ink prototypes often struggled with repeated flexing or accidental bumps, leading to display failures . Manufacturers now develop more robust flexible substrates and advanced encapsulation techniques to protect the delicate E-Ink particles . The challenge remains substantial, as users report concerns about screen damage from normal daily activities.

Durability depends on several key interacting factors. The type of flexible substrate chosen is paramount for resilience; polymers like polyimide or PET are common . Encapsulation layers must protect E-Ink microcapsules and maintain their alignment during bending or creasing . How the display integrates into the fabric itself also dictates overall toughness and resistance to delamination from impacts . A truly durable E-Ink garment needs to withstand thousands of flex cycles without image degradation or pixel failure.

Engineers are battling the fundamental physics of flexibility here. Potential solutions involve advanced polymer substrates offering enhanced resilience and foldability . Some designs place the E-Ink layer on a neutral stress plane, minimizing stress during bending . Smart textile integration, using strategic hinge designs, protective coatings, or cushioning mechanisms, seeks to distribute mechanical stress and absorb impact energy across the garment . Achieving robust durability involves complex design trade-offs and material science breakthroughs.

Laundry Day Dilemma: Can Your E-Ink Shirt Survive the Wash?

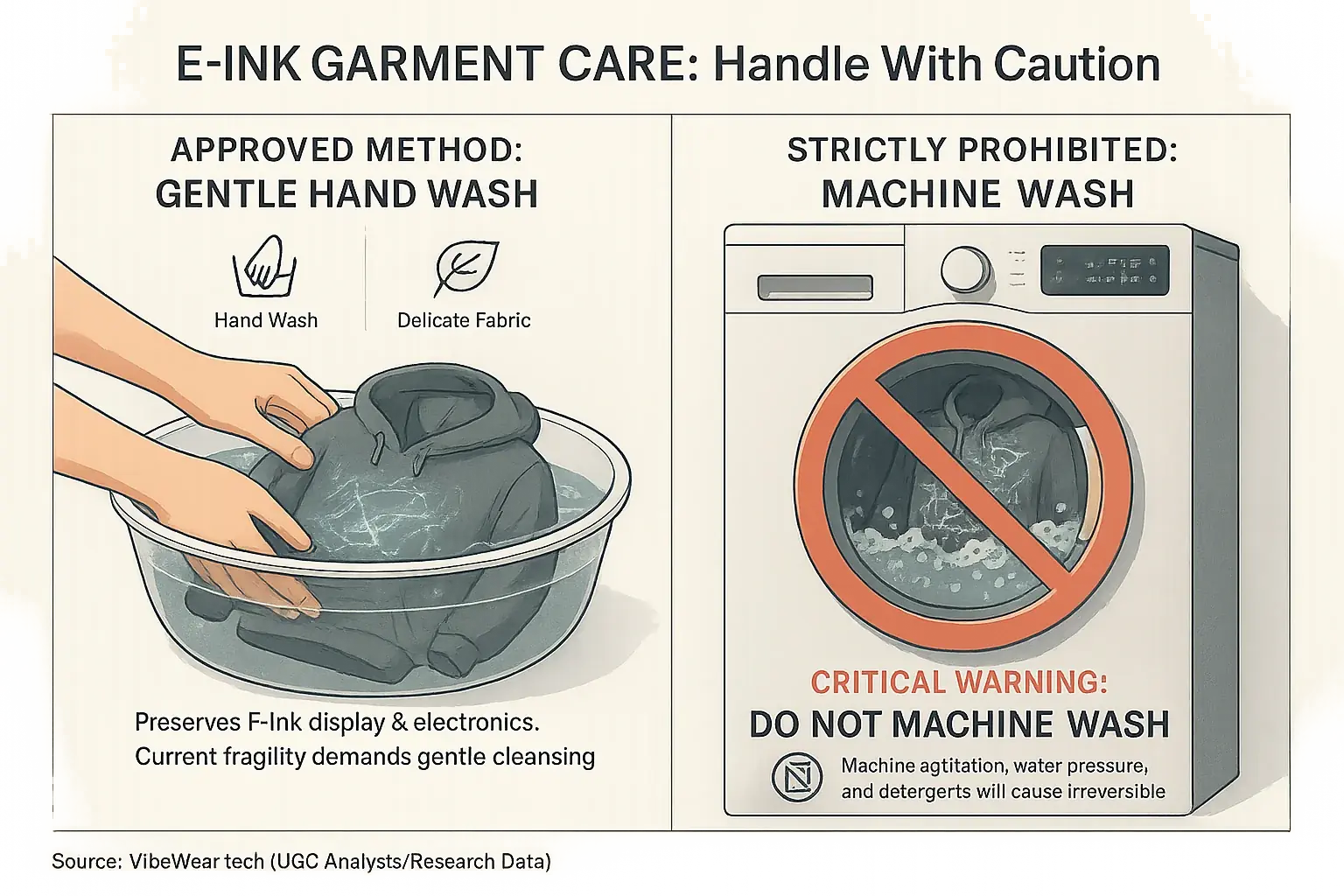

You wear clothes; they get dirty. So, can you just toss your E-Ink hoodie in the washing machine? This simple act presents a huge hurdle for mood-adaptive streetwear. A fundamental user need.

Our investigation into real-world usage scenarios reveals a hard truth. Current E-Ink displays and integrated electronics react badly to water. Detergents cause significant damage. A washing machine's agitation can destroy these delicate components. Owners of early smart garments know this frustration. Many pieces demand specialized care. Washing often makes them unwearable.

Textile engineers wrestle with fundamental material science here. Sealing tiny electronics against persistent moisture is tough. Conductive threads can corrode. This breaks vital connections. Display integrity often fails under chemical attack from detergents. Remember: 'water-resistant' rarely means 'fully machine washable'.

Solutions are emerging. Advanced waterproof encapsulation, like conformal coatings, offers new hope. Modular designs allow easy electronic removal before washing. Future flexible circuits might survive the spin cycle entirely. True washability remains a 'holy grail' for widespread E-Ink fashion adoption. This unlocks everyday practicality.

Keeping the Vibe Alive: Powering E-Ink & Sensors on the Go

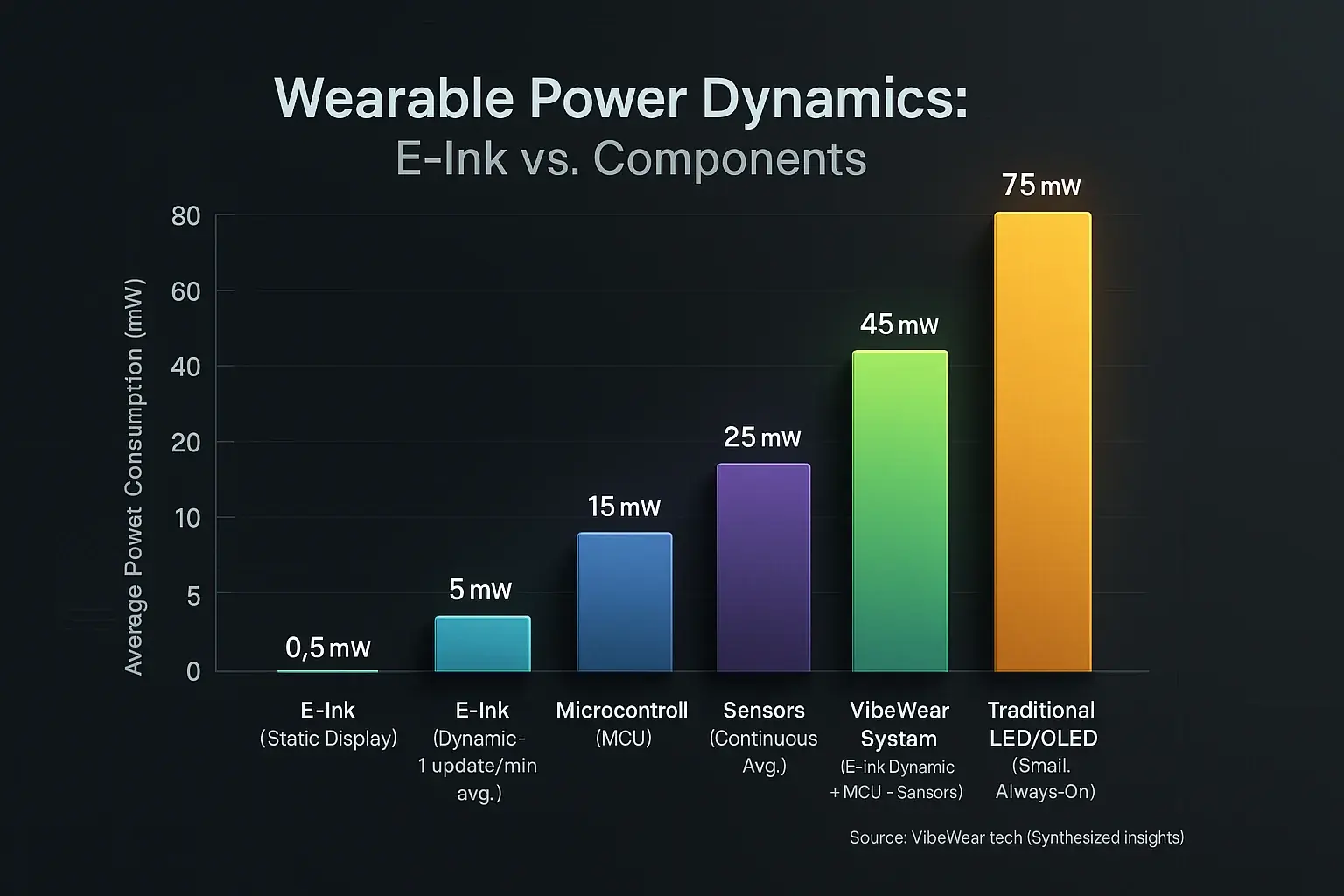

What good is a smart garment if its battery drains quickly? E-Ink displays sip power when static. Dynamic updates and constant sensor activity demand significant energy. This makes the total power budget for E-Ink apparel surprisingly complex.

Current wearables face a hard truth. Many power sources remain too bulky. They feel rigid. This compromises comfort and aesthetics. Users will not adopt clothing with perceptible, uncomfortable weight; nightly charging presents another major hurdle.

Power management for E-Ink apparel is a delicate act. Designers balance display refresh rates. Sensor polling needs thought. Connectivity features add demand. Miniaturized, flexible batteries are essential, integrating seamlessly into fabric.

Our deep dive reveals exciting power solutions. Flexible batteries bend with fabric; wireless charging offers plug-free ease. Imagine clothing harvesting solar power or your body's kinetic energy. The holy grail is truly invisible, long-lasting power. This innovation makes E-Ink fashion genuinely wearable.

The Price Tag: Cost & Manufacturing Realities of E-Ink Fashion

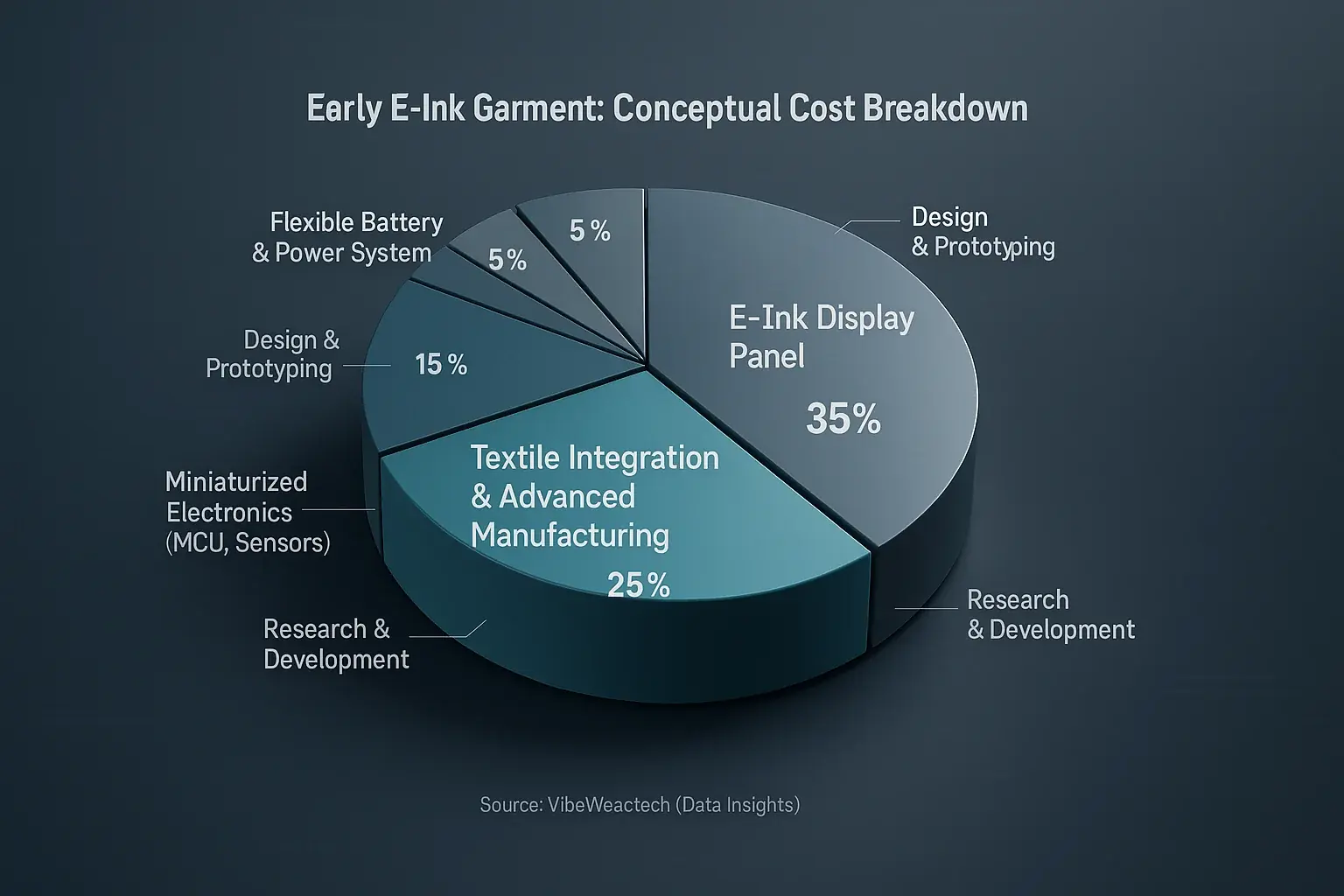

Who really wants a smart shirt costing more than their monthly rent? E-Ink apparel generates excitement. Its current price point, however, presents a significant hurdle. Mass adoption remains a distant prospect for now. The economic reality is that these are not your average t-shirts.

The unspoken truth? Costs climb far beyond the E-Ink panel itself. Specialized manufacturing processes contribute heavily. Integrating multiple sensitive components requires precision. Research and development investments are also factored into early product prices. Early adopters, in essence, help fund this pioneering technology. This is a common pattern for emerging tech.

Several key elements drive these high costs. E-Ink display production is complex. The unique ink, with its charged microcapsules, is expensive. Manufacturing the Thin-Film Transistor (TFT) backplane also adds considerable expense. Miniaturizing electronics like microcontrollers and sensors for flexible wear increases costs further. Integrating these components into textiles without losing durability or washability is labor-intensive. Economies of scale are simply not present yet.

So, what could lower these prices for mood-adaptive streetwear? VibeWear's analysis points to several pathways. Mass production will eventually bring efficiencies. Modular designs might simplify the complex assembly process. Material science breakthroughs could reduce individual component costs, from displays to flexible batteries. Price reduction is absolutely vital. E-Ink fashion needs this to move beyond a niche luxury item into everyday wardrobes.

Ready for the Vibe? Your E-Ink Apparel Challenge Mitigation Checklist

Check the solutions you believe a conceptual E-Ink garment possesses:

This tool guides your E-Ink apparel assessment. It helps you evaluate how conceptual garments might integrate solutions. Key challenges demand smart mitigation. Durability. Washability. Power. Cost. Understanding these specific fixes directly empowers your informed choices when considering new tech. Clear insight makes for confident decisions.

E-Ink apparel still presents specific hurdles. This is undeniable. Yet, innovation relentlessly tackles these obstacles, showing clear progress. Progress accelerates daily. VibeWear's research confirms promising developments in materials and power. Stay informed about these advancements. Look for products featuring strong, practical solutions. Your awareness fuels better design outcomes. The future of expressive tech is arriving.

Overcoming the Hurdles: The Future Outlook for E-Ink Apparel

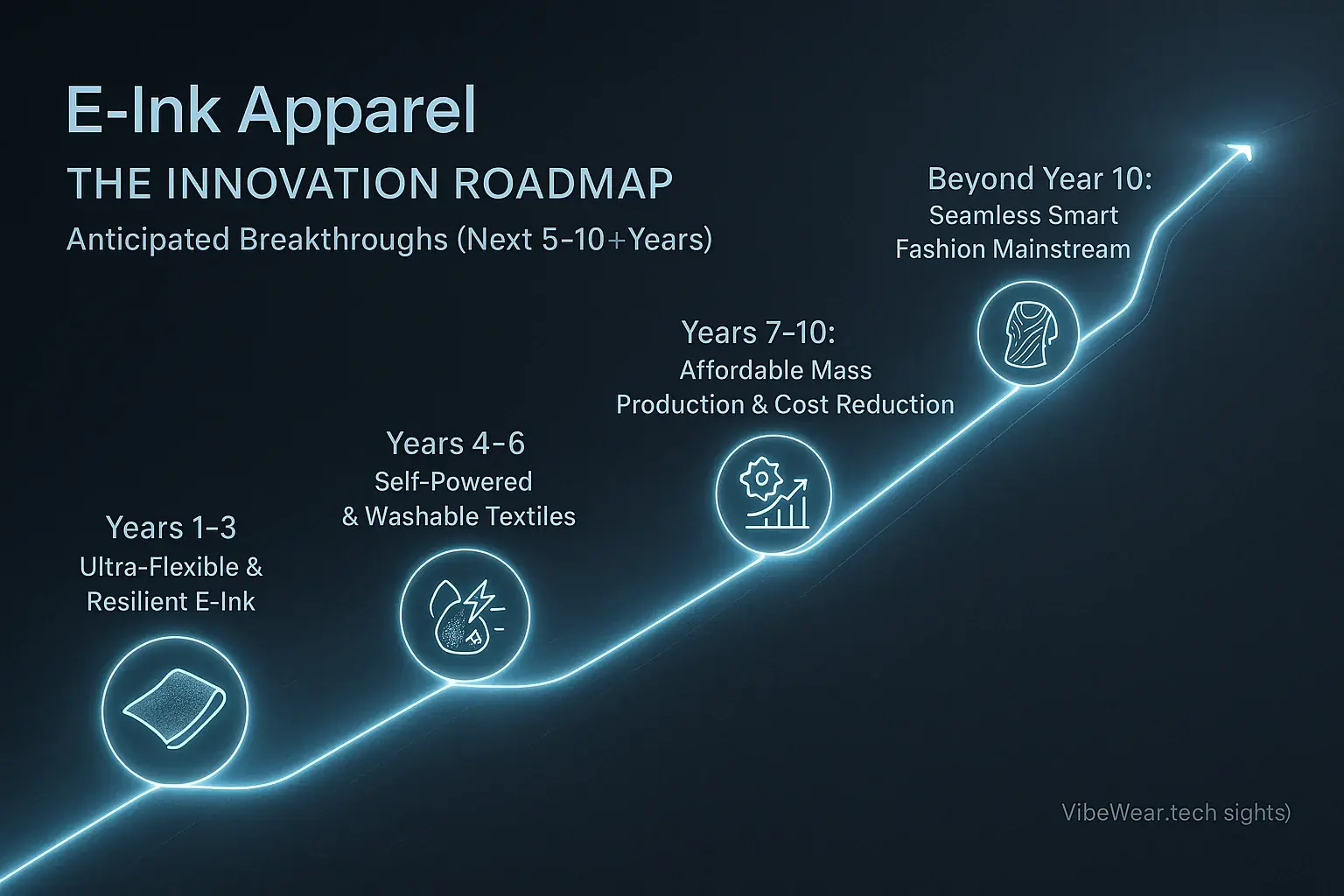

Yes, the hurdles for E-Ink apparel are real. But innovation is accelerating. VibeWear's analysis of industry trends shows flexible electronics and smart textiles are evolving rapidly. Researchers and developers worldwide actively tackle current E-Ink apparel limitations. This progress signals a vibrant future.

Key research areas promise transformative solutions. New materials will enable extreme flexibility for displays. Advanced encapsulation techniques are boosting durability. Efficient energy harvesting from textiles could power garments sustainably. Scalable manufacturing processes are set to reduce costs. These advancements are the next big steps. They will make mood-adaptive E-Ink apparel truly mainstream.

The future of E-Ink fashion extends beyond current possibilities. A relentless drive motivates the industry. This commitment aims to overcome every obstacle. Dynamic, expressive clothing will become a practical reality for everyone. VibeWear sees this exciting path clearly.

Related Insight: Keeping the Vibe Alive: Powering E-Ink & Sensors in Clothing

E-ink displays animate your style. Their transformation demands energy. This presents a core design challenge. Powering persistent expression without bulky constraints is vital. VibeWear's analysis underscores this critical hurdle.

Unlocking truly seamless VibeWear hinges on breakthroughs here. Advanced power solutions become essential. Think flexible batteries. Consider kinetic energy harvesting. Keeping the vibe alive, the very pulse of responsive clothing, forms the next frontier VibeWear is keenly exploring for you.