The Invisible Seam: Why Integrating Tech into Textiles is So Hard (and Why It Matters)

Making advanced tech disappear into clothing is the core challenge. Imagine sewing a delicate smartphone screen into your favorite hoodie. It feels like a brick. It breaks the first time you bend your arm. That is the fundamental test. True wearable technology demands more than surface attachment. Tech must merge seamlessly, weaving into the fabric itself.

This deep integration is absolutely critical. If it's clunky or stiff, it's not fashion. It remains a prototype. It often falls apart in the wash. The real magic happens when the tech becomes invisible. It must feel comfortable. It needs durability for daily wear. This is where the future of VibeWear truly begins. Many overlook this truth. They do not realize the sheer engineering puzzle. Making E-Ink displays bend, stretch, and survive laundry is incredibly complex. Biometric sensors must still read your pulse with precision.

This 'integration puzzle' has several key pieces. Flexibility allows fabric to move naturally. Washability remains a massive hurdle for everyday smart fabrics. Powering these embedded systems without bulky batteries is a constant quest. Manufacturing advanced textiles at scale presents its own revolution. We investigate these.

The Bend Test: Making E-Ink & Circuits Survive Real-World Movement

Clothing demands extreme flexibility from integrated electronics. Garments constantly bend. They stretch. They twist. A VibeWear garment must move with you, surviving countless cycles. This constant motion is a nightmare for traditional, rigid components. Flexible circuitry and the E-Ink display itself directly face this relentless mechanical stress.

Early prototypes often revealed a harsh truth. They frequently failed after just a few hundred bends. The real challenge is not merely initial flexibility. It is ensuring sustained performance after thousands, even tens of thousands, of movement cycles. Think: how often does your elbow bend daily? Many assume 'flexible' means 'indestructible.' The reality of micro-cracks and insidious material fatigue is a persistent battle for engineers striving for true wearability.

Engineers tackle this durability imperative with ingenuity. Stretchable conductive threads represent a significant advance. These threads integrate electronics that flex and move like fabric itself. Advanced encapsulation methods also protect delicate E-Ink layers. These techniques shield components from physical stress without adding prohibitive bulk or stiffness to the garment.

Conductive inks, printed directly onto textiles, are also emerging. This technology allows circuits to be literally 'drawn' onto fabric. These printed connections then bend and stretch seamlessly with the garment's material. This creates truly integrated electronic textiles. A fascinating solution.

The Laundry Test: Making Smart Clothes Washable & Wearable

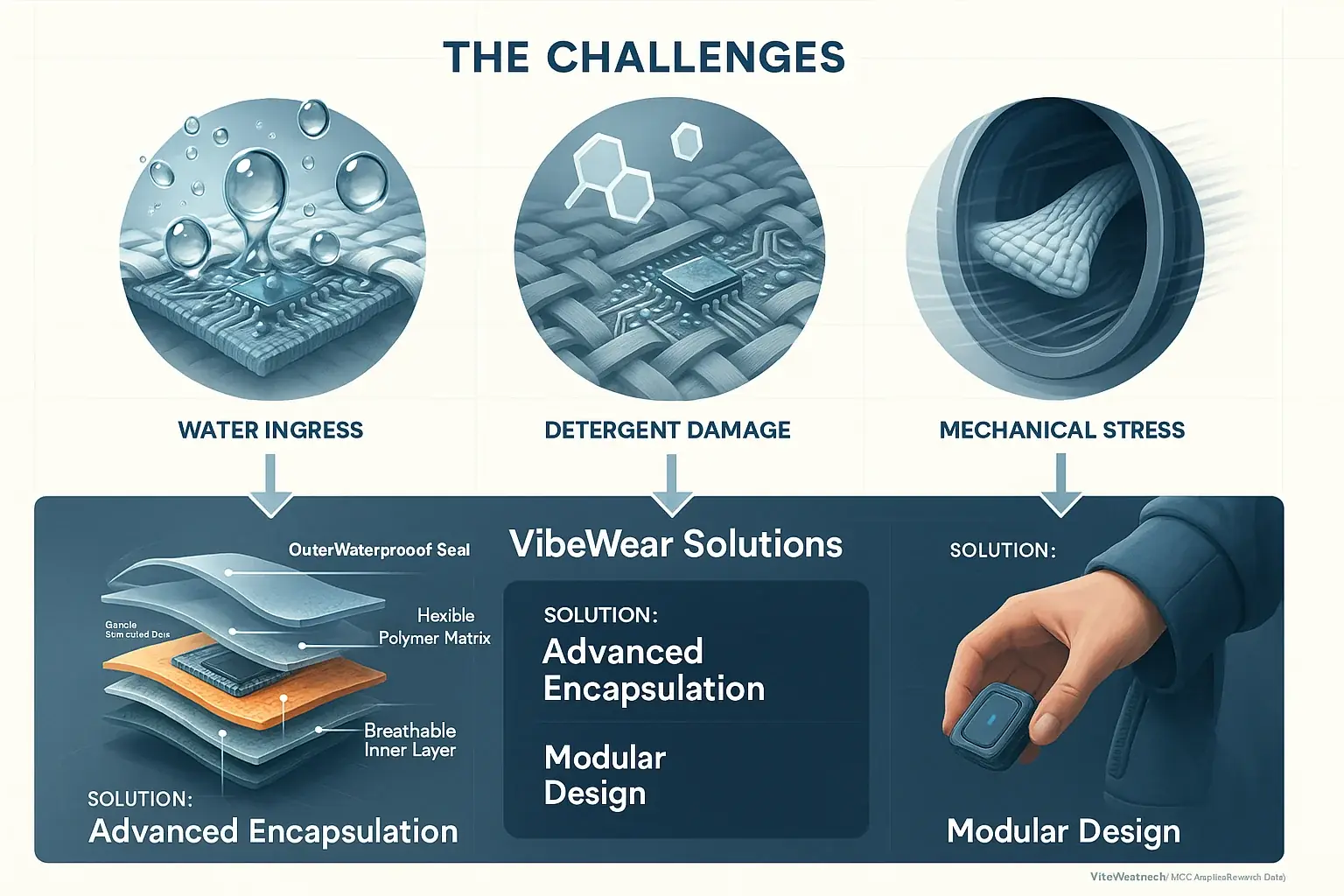

What's the first thing you do with new clothes? You probably toss them in the wash. For VibeWear, that simple act presents a huge design hurdle. Water is an obvious enemy to electronics. Detergents introduce chemical threats. The washing machine’s agitation tests physical integrity of embedded tech.

VibeWear must also feel like your favorite hoodie. Beyond surviving the spin cycle, comfort is non-negotiable. No stiff boards. No itchy wires. No overheating patches press against your skin. Daily wear demands this. Many forget heat; tiny chips generate it. Breathable encapsulation isn't just about waterproofing; it must also vent that component warmth for genuine comfort.

So, how do engineers protect these delicate components? They develop advanced encapsulation methods. These create tiny, flexible, waterproof shields around sensitive electronics. Such barriers protect circuits from water and harsh soaps. Some VibeWear concepts explore modular designs. Users could snap out electronic modules before laundry day.

The base fabric choice profoundly affects comfort. Integration methods also dictate the final feel. Smart textiles are crucial here. These materials offer breathability. And lightness. They must feel soft against the skin. The technology should augment your daily experience, not become an irritation.

Powering the Pulse: Energy & Connectivity in Integrated Apparel

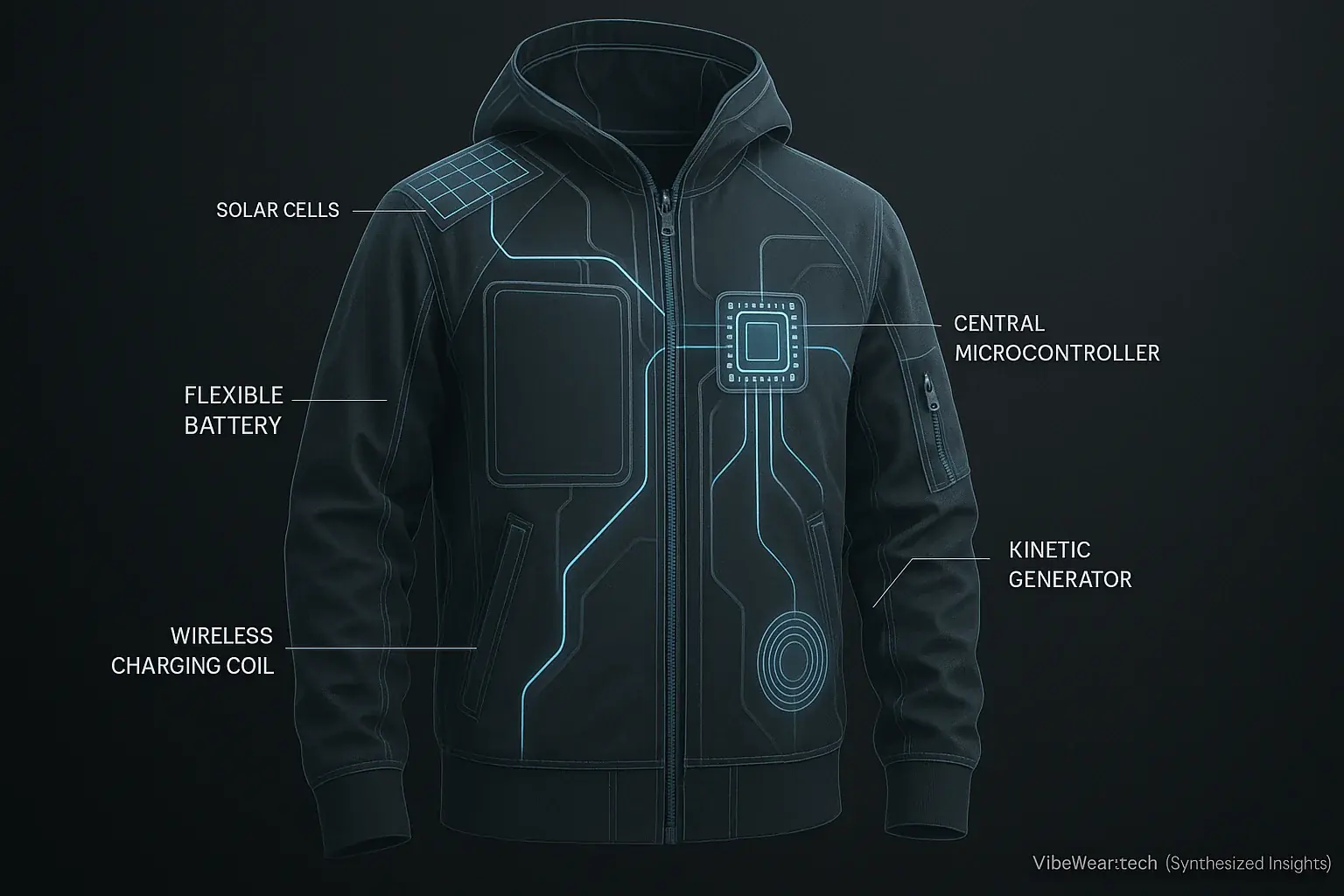

A dynamic E-Ink display and an array of biometric sensors need power. A lot of it. But where do you hide a bulky battery in sleek streetwear? How do you charge it conveniently? Traditional batteries are often too rigid for truly integrated clothing.

Smart garments also need to talk. They connect to phones and cloud services. Seamless, low-power data transfer remains a puzzle. Many assume wireless means 'always on.' This constant drain from Wi-Fi or Bluetooth quickly kills tiny wearable batteries, frustrating users.

Researchers are developing paper-thin, flexible batteries. These batteries conform to the garment's shape. Energy harvesting technologies, like tiny solar cells woven into fabric, also promise a future. Kinetic generators capture movement. These methods aim for self-powered apparel.

Low-power Bluetooth (BLE) is key for phone connections. BLE conserves vital battery life. Future VibeWear might even use textile-integrated antennas. These could ensure more robust, longer-range communication. Your vibe then stays always connected.

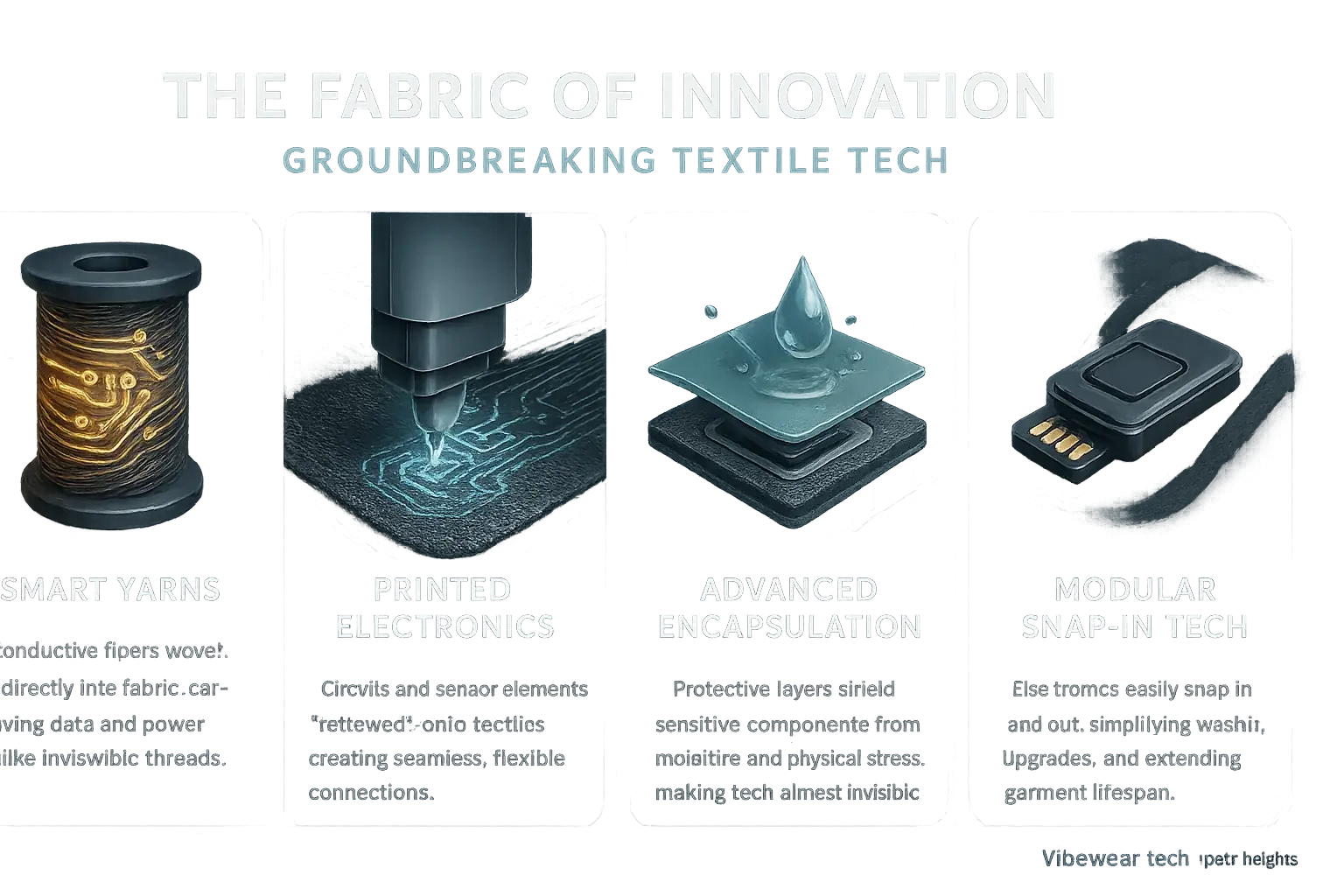

The Fabric of Innovation: Groundbreaking Solutions Weaving Tech into Textiles

Despite the hurdles, innovators are making incredible strides. The lab breakthroughs of yesterday are quickly becoming the practical solutions of today, paving the way for truly integrated VibeWear.

Smart yarns, woven directly into fabric, carry data and power like invisible threads. Printed electronics allow circuits and sensor elements. These get literally 'tattooed' onto textiles. This process creates seamless, flexible connections. Here is an unspoken truth. Many might not realize how much the textile industry itself is evolving, with new weaving techniques specifically designed to accommodate delicate electronic components without compromising comfort or drape.

Advanced encapsulation techniques now protect sensitive components. They shield from moisture. They guard against physical stress. These layers make tech almost invisible. Modular designs also offer a clever workaround. You can easily snap electronics in and out. This simplifies washing and upgrades. The garment's lifespan extends.

These innovations are transforming clothing from a passive material into an active, intelligent interface. The future of fashion isn't just about what you wear; it's about how your clothes interact with you and the world.

From Prototype to Production: Scaling Up Smart Textile Manufacturing

Creating a VibeWear prototype is one thing. Producing thousands affordably is another beast. Smart textile manufacturing at scale presents unique challenges.

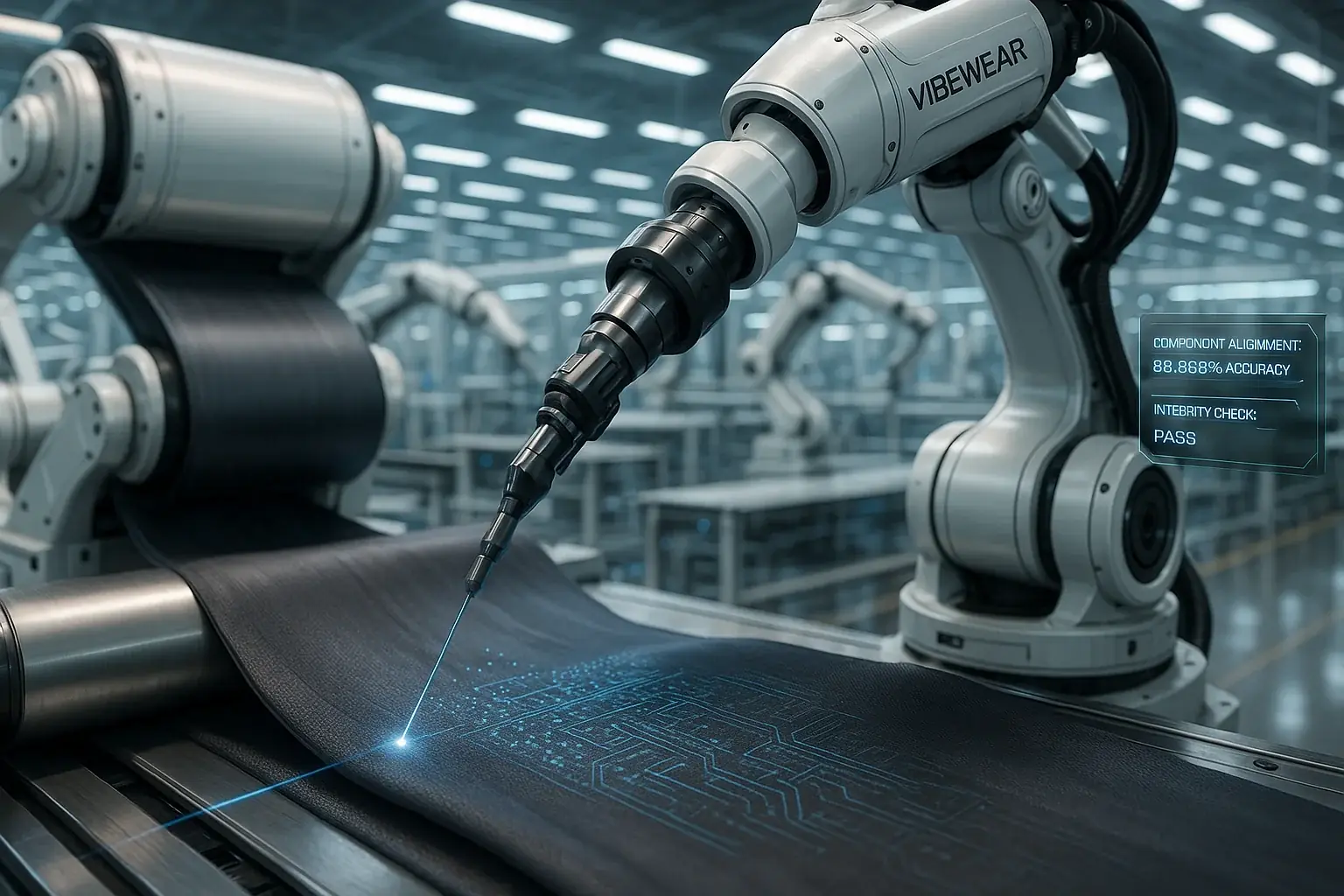

Integrating electronics into textiles requires precision. A tiny misalignment can ruin garments. Ensuring consistent quality across mass production lines is a major hurdle. Many don't realize this. Standard textile machinery often isn't gentle enough for these delicate components. This requires new, specialized manufacturing processes.

New automated processes are emerging. Pick-and-place robotics adapt for flexible substrates. Advanced laser cutting helps. Precise bonding techniques integrate components securely. They avoid damaging the fabric.

Scaling these complex processes directly impacts VibeWear's final cost. Manufacturing methods mature. Efficiency increases. VibeWear expects prices to become more accessible. This brings adaptive fashion closer to the mainstream.

The Future is Woven: A Seamless Blend of Fashion & Technology

Initial hurdles once challenged us; electronics needed to bend and wash. Groundbreaking solutions in smart yarns and precise manufacturing now illuminate the path. The journey toward truly integrated VibeWear is clearly unfolding. Our core vision remains constant. Technology must disappear, seamlessly woven into the very fabric of your apparel.

This evolution is not just about showcasing cool gadgets. VibeWear works to create clothing that genuinely enhances your daily life. Your apparel will express your innermost mood, intuitively adapting to your world. You will not even consciously register the sophisticated tech inside. Your clothes become a true, seamless extension of you.

The future of fashion is not simply smart. It is woven. Imagine technology and textiles merging with absolute completeness. They become one. This fusion unlocks a new canvas for self-expression and vibrant interaction.